PRODUCTS

- Mechanical seal of boiler feed pump

- Mechanical seal of circulating pump

- Slurry pump mechanical seal

- Mechanical seal of desulfurization

- Mechanical seal of agitator

- Compressor mechanical seal

- Sewage pump mechanical seal

- Chemical pump mechanical seal

- Metal bellows mechanical seal

- Heat conduction oil pump mechanical

- Mechanical seal of sanitary pump

- Clean water pump mechanical seal

- Mechanical seal of booster pump

- Air-conditioning pump mechanical se

- Mechanical seal of reaction kettle

- Mechanical seal of Chinese standard

- Mechanical seal of paper pulp pump

- Mechanical seal of pressure screen

- Water pump accessories

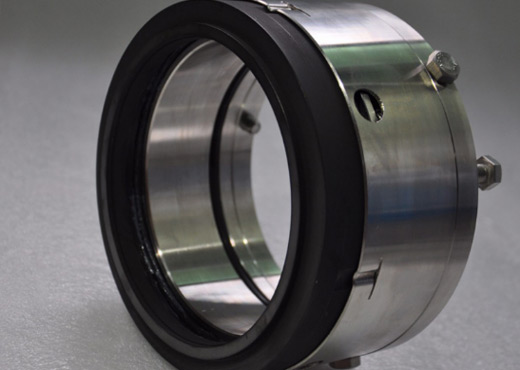

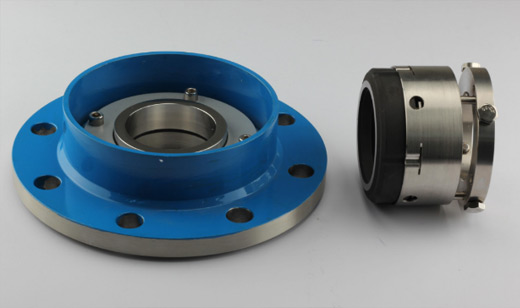

204B mechanical seal is mainly used in vertical reaction kettle, fermenter, stirring tank and tank containers. When the pressure is greater than 0.4MPa, a pressure balancing tank must be used. When the temperature is greater than 180 ° C, a cooling water tank must be installed. 204F and 204FF can be used for sealing reactors without liquid lubrication by selecting suitable friction pair materials, such as fermenter and seed tank. The 204FF is set to static ring pair for quick repair and replacement.

Working parameters

Rules: 30 ~ 180 mm

Pressure: 0.8 Mpa or less

The temperature: - 40-180 ℃

Speed: ≤500r/ min

Axial channeling momentum: ±0.5mm

Material combination

Sealing end face: graphite, silicon carbide, 304 butt welding

Auxiliary seal: fluorine rubber

Metal component: SUS304, SUS316L

The product description

Single face

balanced

Arbitrary spin to

In the development and design of any product, we follow the principle of installation size standardization. That is, the installation size of this type of mechanical seal is in line with the domestic HG5-748-78 standard (referred to as 78 standard) and HG2098-91 standard (referred to as 91 standard).